Pioneering Progress: A Deep Dive into Electric Vehicle Motor Design and Manufacturing

Pioneering Progress: A Deep Dive into Electric Vehicle Motor Design and Manufacturing

In the dynamic landscape of electric vehicles (EVs), our project represents a pioneering effort, delving into the complexities of EV motor design and manufacturing. This comprehensive blog offers a detailed exploration of our project, highlighting its objectives, goals, methodologies, expected outcomes, contributions to technology, industry benefits, and the challenges encountered.

Project Summary

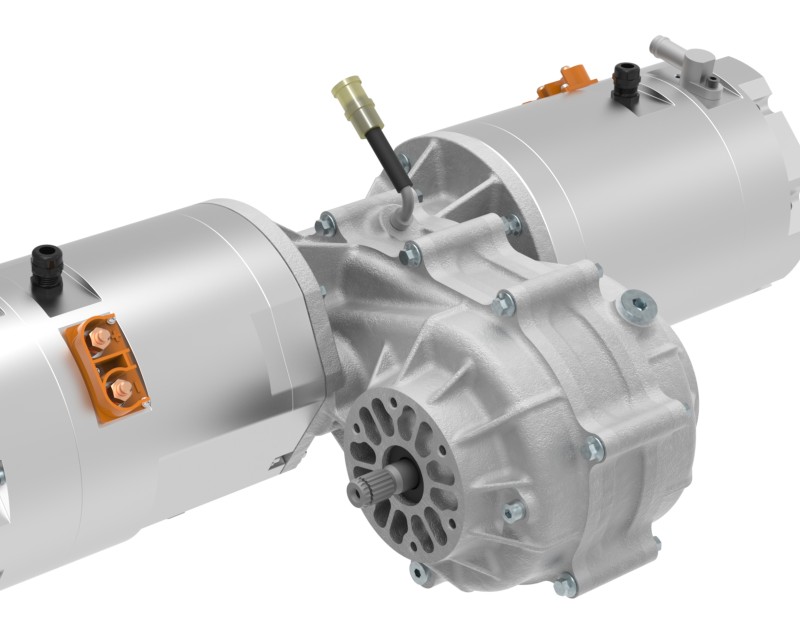

The crux of our project revolves around the intricate world of electric vehicle motor design and manufacturing. This journey spans a diverse range of activities, commencing with the fundamentals of motor design and progressing seamlessly into the realm of finite element analysis. Our commitment to incorporating optimization techniques underscores our dedication to improving performance and efficiency, critical objectives in the ever-evolving field of electric vehicles.

Project Goals

At the heart of our project lie primary goals encompassing efficiency, performance, and sustainability. Key objectives include achieving high efficiency, optimal performance, reduction in weight and size, cost-effectiveness, durability, reliability, seamless integration with vehicle systems, and compliance with regulations.

Project Objectives

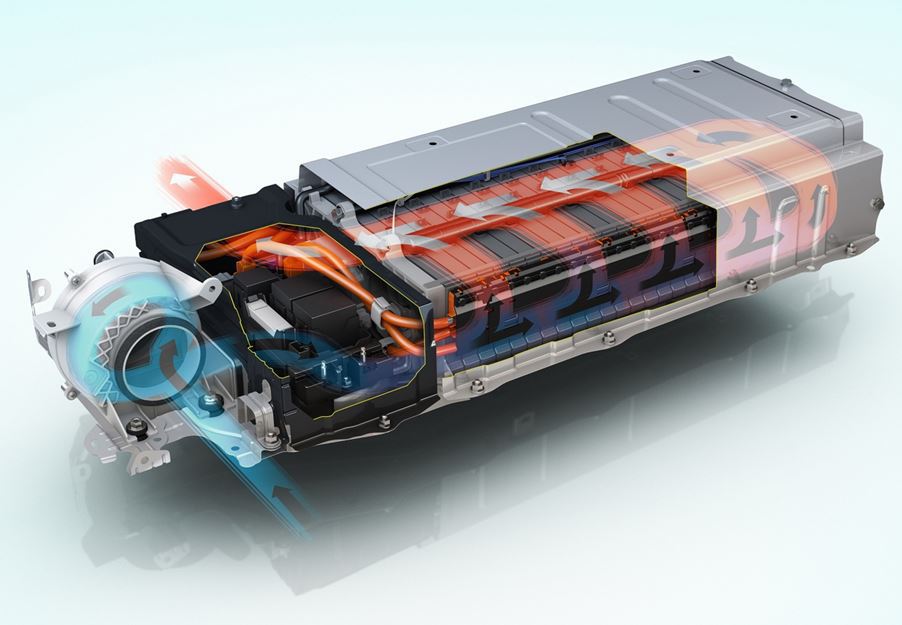

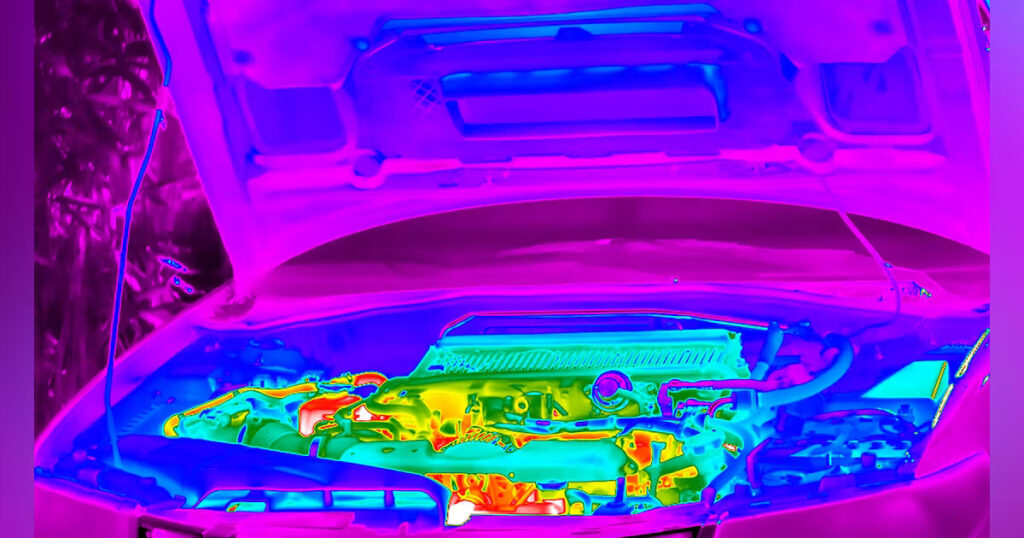

Delving deeper, our specific objectives crystallize the vision for this project in the field of motor design and manufacturing for electric vehicles. Actions include optimizing the design to reduce resistive losses, exploring advanced materials for power density enhancement, investigating lightweight materials for weight reduction, streamlining manufacturing processes for cost optimization, implementing advanced thermal management, ensuring precision fabrication, and achieving seamless integration with vehicle systems.

Research Methods and Experiments:

Our project’s strength lies in its diverse and advanced research methods:

Project Outcomes and Contributions:

Expected Outcomes:

Anticipated outcomes transcend the ordinary, envisioning the development of an advanced and optimized electric vehicle motor. This includes a meticulously designed high-performance motor, improved energy conversion efficiency, a compact and lightweight motor, cost-effective manufacturing solutions, efficient thermal management, a motor meeting stringent durability and reliability standards, seamless integration with vehicle systems, compliance with safety and environmental standards, and a traction motor satisfying specified requirements.

Contributions to Technology:

Our project’s broader vision extends beyond outcomes, aiming to contribute significantly to advancements in electric vehicle technology. Initiating a localized manufacturing ecosystem, fostering skill development, exploring cost-effective solutions, designing modular components, catalyzing local entrepreneurship, and launching awareness campaigns form the cornerstone of our contributions.

Industry Benefits:

Our project seeks to initiate the development of a localized manufacturing ecosystem for electric vehicle components. By leveraging existing resources and engaging local suppliers and small-scale industries, we envision paving the way for indigenous production, even in the absence of large-scale manufacturing facilities.

Challenges Faced:

The journey has not been without its challenges, spanning design analysis complexities, manufacturing intricacies, and fabrication hurdles. However, rather than acting as impediments, these challenges have become catalysts for innovation, propelling us to continually refine our approach.

Acknowledgments:

Our heartfelt gratitude extends to the dedicated team members and collaborators who have played a pivotal role in shaping and steering this project towards excellence.

Stay Tuned for Updates:

Follow our journey for real-time updates and insights as we navigate this exciting and transformative path in electric vehicle technology.

Conclusion

As we navigate the intricate landscape of electric vehicle motor design and manufacturing, our project stands as a testament to innovation, dedication, and the pursuit of excellence. Embracing challenges and leveraging cutting-edge research methods, we are on a transformative path that promises to redefine the future of electric vehicle motors.